Understanding CAD Drawings Flange

What are CAD Drawings?

Computer-Aided Design (CAD) drawings are digital representations of physical objects, created using specialized software. These drawings are essential in engineering, architecture, and manufacturing processes as they facilitate precision and accuracy in design. CAD allows for the creation of detailed 2D drawings and 3D models, which can be manipulated and analyzed for structural integrity, material usage, and design feasibility. In the context of flanges, CAD drawings help engineers visualize the component’s dimensions, tolerances, and specifications before material selection and fabrication begin. Utilizing cad drawings flange can significantly enhance the workflow in projects involving piping and structural connections.

Importance of Flange Specifications

Flange specifications are critical because they define the standards necessary for ensuring compatibility, safety, and functionality in piping systems. Specifications encompass materials, dimensions, pressure ratings, and load capabilities. Accurate flanges are paramount in preventing leaks, ensuring the stability of connections, and accommodating thermal expansion. Inadequately specified flanges can lead to catastrophic failures, resulting in downtime, safety hazards, and significant financial losses. Establishing precise specifications through CAD drawings helps mitigate these risks, offering a comprehensive framework for engineers and designers to work with.

Key Applications in Engineering

CAD drawings of flanges find numerous applications across various engineering disciplines. Some of the primary sectors utilizing these designs include:

- Piping Engineering: Flanges form integral connections in piping systems, used to connect pipes, valves, and other equipment.

- Structural Engineering: In constructing buildings, flanges enable connections between structural components like beams and columns.

- Manufacturing Industry: Flanges are pivotal in the assembly of machinery and equipment, where precision alignment is crucial.

- Automotive and Aerospace: In these industries, flanges are used in various components, including exhaust systems and engine parts, to ensure safe and efficient performance.

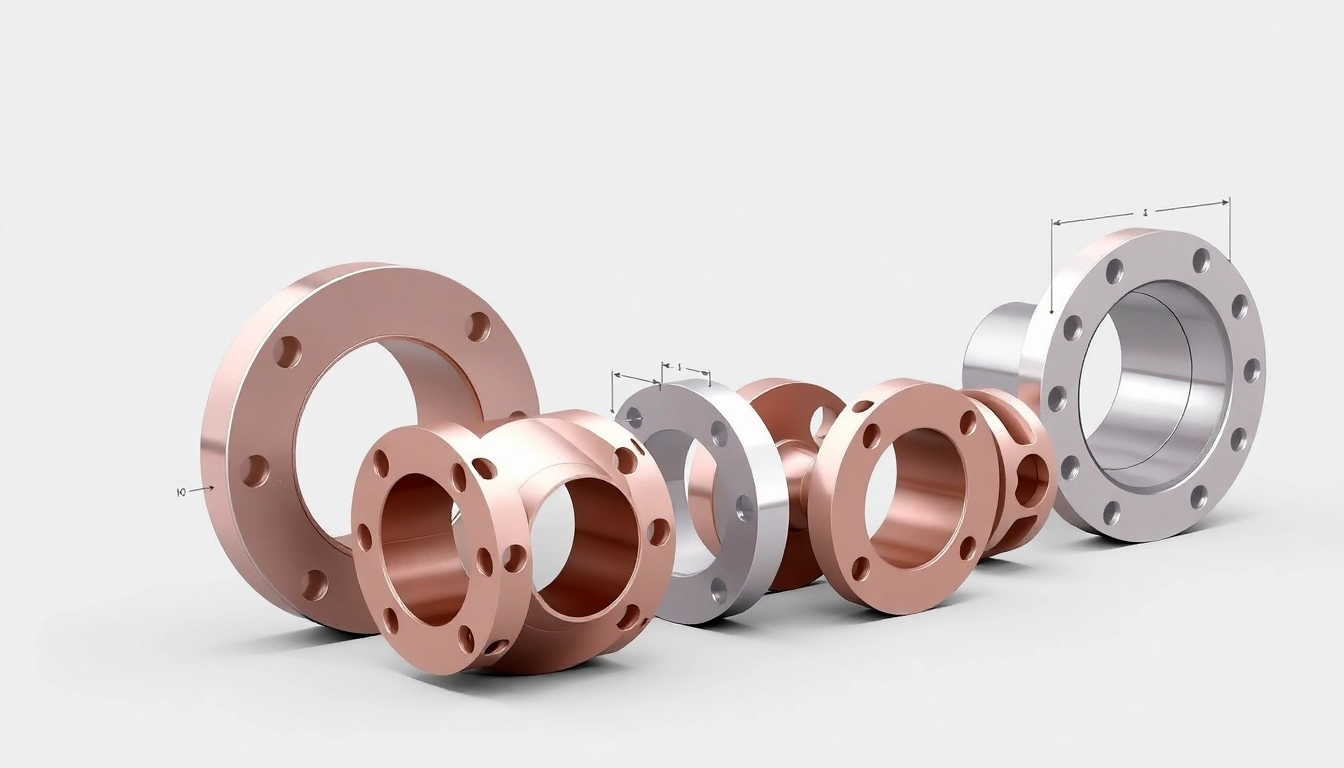

Types of Flanges in CAD

Weld Neck Flanges

Weld neck flanges feature a long neck that provides a gradual transition from the flange to the pipe. This design reduces stress concentrations and is particularly suitable for high-pressure applications. They are commonly used in chemical processing, oil and gas industries, and pressure vessels. When creating CAD drawings of weld neck flanges, considerations include the appropriate piping diameter, material thickness, and weld preparation type to ensure optimal performance.

Slip-On Flanges

As the simplest flange type, slip-on flanges are designed to slide over the pipe’s end. They are versatile and easy to install, making them popular in lower-pressure applications. These flanges are commonly used in water systems, HVAC applications, and light industrial uses. CAD drawings for slip-on flanges must accurately reflect the pipe’s outer diameter and necessary dimensional tolerances for proper installation.

Blind Flanges

Blind flanges are solid disks that seal off the ends of pipes or vessels, efficiently containing pressure and preventing leaks. They are crucial in maintenance procedures, allowing for the isolation of sections of piping without requiring dismantling. Blind flanges are sourced based on the relevant pressure and temperature ratings, and when drafting their CAD representations, design considerations should ensure compliance with Berthing and Safety standards.

Best Practices for Creating CAD Drawings Flange

Utilizing CAD Software Effectively

When creating CAD drawings for flanges, it is essential to utilize the software’s functionalities to maximize efficiency. Key practices include:

- Layer Management: Organizing components into different layers enhances clarity and ease of edits.

- Dimensioning Tools: Use dimensioning tools judiciously to provide clear specifications, avoiding ambiguity in measurements.

- 3D Modeling: Employ 3D modeling features to visualize the interaction between flanges and other components in the assembly.

Standards and Compliance

Compliance with industry standards cannot be overstated when creating CAD drawings for flanges. Familiarity with organizations such as the American National Standards Institute (ANSI), International Organization for Standardization (ISO), and American Society of Mechanical Engineers (ASME) is essential. Each specification provides guidelines on dimensions, pressure ratings, and manufacturing processes, ensuring that the designed flanges meet rigorous safety and performance criteria.

Common Pitfalls to Avoid

CAD drawing errors can lead to significant project delays and additional costs. To minimize mistakes:

- Avoid inaccurate dimensions by consistently verifying measurements against industry standards.

- Double-check material specifications to ensure they suit the application requirements.

- Seek peer reviews of drawings before finalization for fresh perspectives on design accuracy.

Case Studies: Flange Applications in Industry

Pressure Vessels

Pressure vessels require precision-engineered flanges to manage extreme pressure changes safely. In a case study involving an oil refinery, innovative CAD designs allowed the creation of custom flanges that adhered perfectly to specific operational environments. Rigorous testing against standard regulatory codes ensured that the products were not only effective but also compliant with both safety and operational standards.

Pipelines

In pipeline construction, flanges enable the connection between various sections with corrosion-resistant materials. A notable project involved the construction of a natural gas pipeline, where an array of CAD-generated flanges reduced installation times significantly while enhancing safety protocols. Flange designs featured bespoke pressure ratings to accommodate varying environmental conditions, demonstrating the critical role of CAD in real-world applications.

Specialty Equipment Manufacturing

In the specialty equipment sector, such as aerospace manufacturing, precision is paramount. A case study involving specialized connectors utilized custom-designed flanges with specific tolerancing verified through CAD simulations. As a result, the equipment passed stringent quality tests, and successful integration into aviation systems was achieved. Continued partnerships with CAD specialists streamlined future product iterations, emphasizing the importance of robust CAD design processes.

Future Trends in CAD Drawings Flange

Integration of Advanced Technologies

The future of CAD drawings, particularly for flanges, will increasingly involve advanced technologies like Artificial Intelligence (AI) and machine learning. These technologies can enhance predictive modeling capabilities, allowing for simulations that anticipate performance under various operating conditions. This advancement is expected to shorten design cycles significantly and reduce potential errors in the manufacturing stage.

Sustainability in Design

With heightened awareness of environmental impacts, there is a growing push toward sustainable design practices in engineering. CAD technology allows engineers to model and simulate the environmental impact of materials and designs throughout product lifecycles. The focus on using recyclable materials and reducing waste in the production of flanges is becoming standard practice, impacting design choices made in CAD.

Emerging Standards and Innovations

The engineering industry continuously evolves, with new standards and protocols emerging to govern flange design requirements. Upcoming regulations may involve enhancements in safety protocols and performance metrics, which CAD software will need to incorporate to stay compliant. Regular updates and training in evolving standards are crucial to maintaining service excellence in flange design.