Introduction to Needle Guns

In the realm of metalworking, the needle gun has established itself as an indispensable tool for professionals and hobbyists alike. As technology evolves, so does the efficiency and effectiveness of these tools, making them essential for a range of applications including automotive repair, ship maintenance, and general surface preparation. Understanding the mechanism, applications, and benefits of needle guns is crucial for anyone looking to enhance their metalworking capabilities.

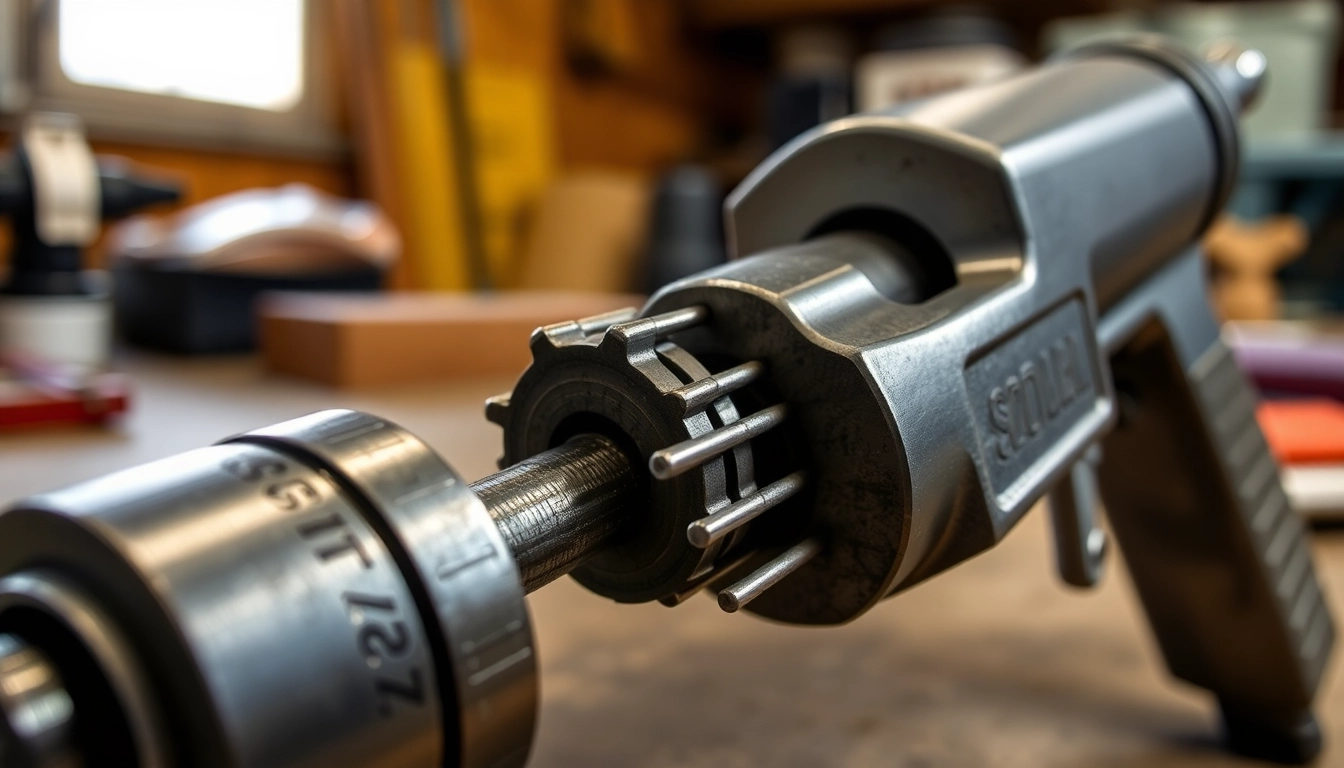

What Is a Needle Gun?

A needle gun, often referred to as a needle scaler, is a pneumatic or electric tool designed to utilize rapid hammering action to drive multiple needles against a surface. This unique mechanism allows for the precise removal of rust, old paint, mill scale, and other contaminants from metal surfaces. The needles, typically made from hardened steel, vibrate at high speeds, effectively dislodging unwanted material without damaging the underlying substrate.

The History of Needle Guns in Metalworking

The roots of needle guns can be traced back to the development of pneumatic tools in the 20th century. Originally, these tools were designed to address labor-intensive tasks that often resulted in fatigue and inefficiency. As industries grew, the demand for quicker, more effective tools led to the adaptation of pneumatic technology in the form of needle guns. Their ability to deliver consistent results while improving worker safety made them invaluable in a variety of sectors—from shipbuilding to automotive manufacturing. Today, they’ve been refined through technological advancements to improve performance and user experience.

Types of Needle Guns Available Today

Needle guns come in various configurations to suit different applications. They can be broadly classified into two categories: pneumatic and electric needle guns.

- Pneumatic Needle Guns: Powered by compressed air, these needle guns are favored in industrial settings for their reliability and power. They often provide higher BPM (beats per minute) rates, making them suitable for larger projects.

- Electric Needle Guns: Offering freedom from air compressors, electric needle guns have become popular among DIY enthusiasts and small workshops. They are typically lighter and easier to handle, although they may have lower BPM compared to their pneumatic counterparts.

- Specialized Models: There are also models designed for specific tasks, such as those featuring adjustable speeds or integrated filtration systems to minimize dust exposure during operation.

How Needle Guns Work

The Mechanism Behind Needle Guns

At the heart of a needle gun’s operation is an air-driven mechanism that translates air pressure into rapid needle movement. When activated, compressed air flows through a series of valves and cylinders, causing the needles to vibrate at high speeds. This vibration produces a hammering action that effectively loosens and removes debris from the surface without gouging or damaging the material beneath.

Air Pressure Requirements and Specifications

Each needle gun has specific air pressure requirements that dictate its performance. Generally, a needle gun will operate optimally with a supply of about 8 to 16 CFM (cubic feet per minute) at 90 psi. It is essential to ensure that your air compressor can consistently deliver the required pressure, as insufficient air flow can lead to decreased efficiency and increased wear on the tool. Additionally, using a high-quality air filter can help maintain optimal air quality and prolong the life of the gun.

Choosing the Right Needle Gun for Your Project

Selecting the appropriate needle gun involves considering several factors including the type of material you will be working on, the size of the area needing attention, and the level of portability required. Here are some tips to guide you:

- Project Size: For large industrial projects, a high BPM pneumatic needle gun will perform best. Smaller jobs may be suited to a lightweight electric model.

- Type of Surface: Consider the hardness of the surface materials. Different needle sizes and configurations can optimize performance for specific substrates.

- Ergonomics: Choose a model that fits comfortably in your hand and has features like vibration dampening and adjustable handles to reduce operator fatigue during prolonged use.

Applications of Needle Guns

Surface Preparation in Various Industries

Needle guns have a wide array of applications across different industries. They are primarily used for surface preparation, which is critical in many sectors to ensure optimal adhesion of coatings, paints, or other finishes. Common uses include:

- Marine Industry: Needle guns are widely employed in shipyards for the removal of rust and flaking paint from hulls. This is crucial to maintaining the integrity and aesthetics of vessels.

- Construction: In construction settings, needle guns are essential for preparing metal surfaces for welding or painting by ensuring they are clean and free from contaminants.

- Aerospace: The aerospace industry benefits from needle guns in the maintenance of aircraft components, where precision and quality control are paramount.

Automotive Repair and Restoration

Automotive professionals and enthusiasts use needle guns extensively to restore classic cars or maintain modern vehicles. The tool excels at removing rust and paint from body panels, allowing for a smooth surface for repainting or repairing. A clean surface is not only visually appealing but also crucial for ensuring that new coatings adhere properly without blemishes or imperfections.

Home Improvement Projects

Homeowners undertaking DIY projects often turn to needle guns for various surface preparation tasks. From cleaning old metal fences to renovating furniture, needle guns are effective and efficient. They provide the novice with a tool that simplifies tasks that would otherwise require extensive manual labor.

Benefits of Using Needle Guns

Efficiency in Cleaning and Preparation

The speed at which needle guns operate is one of their greatest advantages. By significantly reducing the time required for surface preparation, they allow professionals to maintain productivity while ensuring high-quality results. With the ability to cover large areas quickly, needle guns help streamline operations in industrial environments.

Precision in Removing Rust and Paint

Needle guns provide a level of precision that is often unmatched by other cleaning methods. The ability to remove layers without gouging or damaging the base material is particularly beneficial when working with delicate surfaces or historical restorations where preserving the integrity of the original material is critical.

Time and Cost Effectiveness

Investing in a needle gun can lead to significant cost savings over time. The reduction in labor hours needed for surface preparation translates to lower project costs. Furthermore, using a needle gun can minimize the need for additional materials, such as primers or rust inhibitors, enhancing overall project efficiency.

Best Practices and Tips

Safety Precautions When Using Needle Guns

While needle guns are effective tools, they must be used with care. Here are essential safety tips to keep in mind:

- Personal Protective Equipment (PPE): Always wear safety goggles, hearing protection, and gloves to protect against flying debris and high noise levels.

- Workspace Preparation: Ensure that the work area is clear of unnecessary materials, and check that there are no electrical hazards present when using pneumatic tools.

- Proper Training: Familiarize yourself with the equipment and its specific operational guidelines to maximize safety and efficacy.

Maintenance Tips for Longevity

Like any power tool, regular maintenance can extend the life of your needle gun. Here are some tips:

- Regular Cleaning: Remove dust and debris build-up regularly to ensure optimal operation.

- Check Hose Connections: Inspect air hoses for leaks or damage, as these can cause loss in performance and efficiency.

- Lubrication: Follow the manufacturer’s recommendations for lubricating moving parts to keep the tool running smoothly.

Common Challenges and Solutions

Using a needle gun is not without its challenges. Here are some common issues and their solutions:

- Insufficient Air Pressure: If the needle gun is not operating at the expected efficiency, check the air compressor settings and hose connections. Ensure that the compressor is in good working order.

- Needle Breakage: Over time, needles can wear out or break. Regularly inspect them and replace as needed to maintain effectiveness.

- Poor Surface Finish: Should the surface finish not meet expectations, adjust the technique used. Different angles and speeds can influence the final outcome.