Introduction to Cabinet Hinge Types

Cabinet hinges are a crucial part of cabinetry and furniture design, providing functionality and accessibility while also contributing to the overall aesthetic. Manufacturers today offer a wide array of cabinet hinge types, each tailored to meet specific needs in both residential and commercial settings. Understanding these options is essential for anyone involved in design, renovation, or construction. By exploring various styles and their applications, one can make informed decisions that enhance both the efficiency and beauty of cabinet installations. For more insights on Cabinet Hinge Manufacturers, this guide serves as a valuable resource.

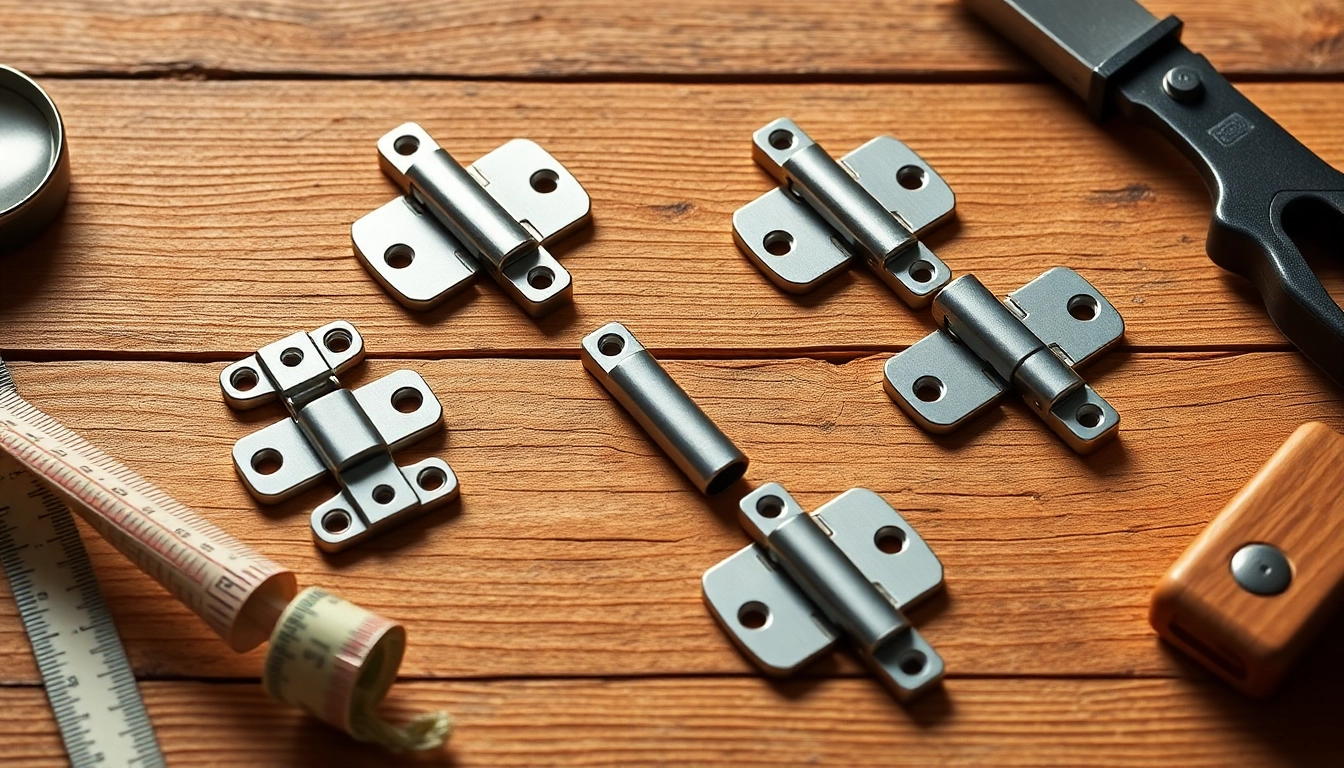

Overview of Different Cabinet Hinge Variants

Cabinet hinges come in several variants, each designed with specific applications in mind. The most common types include:

- Concealed Hinges: These are hidden when the cabinet door is closed, offering a sleek appearance. They are particularly popular in modern kitchens and furniture.

- European Hinges: A subtype of concealed hinges, known for their adjustable nature. They allow for easy alignment adjustments during installation.

- Overlay Hinges: Ideal for cabinets with doors that overlay the cabinet frame, providing a clean look.

- Inset Hinges: Used for doors that sit flush with the cabinet frame, offering a traditional aesthetic.

- Pivot Hinges: These allow doors to swing open from a single pivot point, commonly used in larger cabinet doors.

- Soft-Close Hinges: Equipped with mechanisms that gently pull the door closed, preventing slamming and reducing wear over time.

Understanding these variants helps in selecting the right hinge for specific cabinet designs and user needs.

Common Applications in Residential and Commercial Settings

In residential settings, cabinet hinges are most commonly found in kitchens, bathrooms, and living areas. Depending on the cabinet style—be it traditional or modern—certain hinge types may be more appropriate. For instance, concealed hinges are favored in contemporary kitchens for their minimalist look, whereas traditional wooden cabinet doors may utilize overlay or inset hinges.

In commercial environments, the choice of hinges can be driven by durability and usage frequency. High-traffic areas may benefit from more robust hinge types like pivot hinges or those with soft-close mechanisms to withstand constant use. Additionally, aesthetics may also play a role in commercial interior designs, particularly in showrooms or upscale retail spaces.

Choosing the Right Hinge for your Needs

Selecting the right hinge requires careful consideration of several factors, including door weight and size, cabinet design, and desired functionality. Here are some key points to consider:

- Door Weight: Heavier doors require sturdier hinges. Always check the weight rating of your chosen hinge.

- Material: Choose hinges made from high-quality materials that resist corrosion and wear, especially in areas with moisture.

- Adjustability: Look for hinges that allow for adjustment after installation, which can be essential for ensuring a perfect fit.

- Style: Match the hinge style with your cabinet design for a cohesive look.

Understanding the Manufacturing Process

Materials and Technology Used by Cabinet Hinge Manufacturers

The manufacturing of cabinet hinges involves a variety of materials and technologies that contribute to their durability, aesthetic appeal, and functionality. Materials commonly used include:

- Steel: Often utilized for its strength and durability, providing long-lasting performance in high-usage applications.

- Aluminum: Lightweight and resistant to corrosion, making it suitable for moist environments.

- Brass: Valued for its aesthetic appeal and resistance to tarnishing, often used in decorative hinges.

- Plastic Composite: Ideal for lightweight applications, though less durable than metals.

Modern manufacturing employs advanced technologies like automation, precision machining, and quality control systems to ensure the highest standards of production. Computer-aided design (CAD) software plays a crucial role in conceptualizing and prototyping new hinge designs that meet specific customer needs.

Quality Control and Standards in Hinge Production

Quality control is pivotal in the hinge manufacturing process, as it ensures that products meet both safety and performance standards. Leading manufacturers adhere to international standards, such as ISO 9001, which emphasizes quality management systems. Regular testing of hinges for factors like:

- Load-bearing capacity

- Corrosion resistance

- Durability under repeated use

These tests help manufacturers certify that their products can withstand the rigors of daily use, contributing to customer satisfaction and brand integrity.

Customization Options for Unique Projects

Many manufacturers offer customization options to meet the specific needs of unique projects. Custom hinges can be tailored in size, material, finish, and even functionality. For instance, a restaurant might require special hinges for cabinets that are frequently opened and closed, necessitating soft-close features paired with enhanced durability. Custom solutions can enhance the overall function and appearance of cabinetry while reflecting the brand identity.

Key Features of High-Quality Cabinet Hinges

Durability and Longevity: What to Look For

When evaluating cabinet hinges, durability is a critical factor, especially in high-use applications. Key indicators of quality include:

- Material Composition: Selecting hinges made of high-grade materials will typically ensure a longer lifespan.

- Finish: A sturdy finish prevents corrosion, while also adding to the aesthetic appeal.

- Joint Mechanisms: Well-engineered joints reduce wear and improve overall durability.

Investing in high-quality hinges ultimately reduces the need for replacements and maintenance over time, enhancing the overall value of your cabinetry.

Design and Aesthetics: Enhancing Cabinet Appearance

High-quality cabinet hinges don’t just function well; they contribute significantly to the overall design aesthetic of cabinetry. Available in various styles, colors, and finishes, hinges can complement your cabinet design:

- Finishes: Options range from matte to polished, catering to various design themes.

- Styles: Whether traditional, contemporary, or ornate, the style of the hinge should harmonize with the design of the cabinets.

- Size: Proportionality matters; larger hinges can provide a bold statement, while smaller hinges may blend seamlessly.

This attention to design can make a significant difference in the overall impact of kitchen or furniture renovations.

Soft-Close Mechanisms and Their Benefits

Soft-close hinges have surged in popularity due to their convenience and functionality. These mechanisms provide a controlled closing action that eliminates the risk of slamming, enhancing safety and user experience. The benefits include:

- Noise Reduction: Soft-close hinges offer a quieter operation, ideal for homes with children or open-concept designs.

- Protection for Cabinets: By preventing slamming, these hinges reduce wear on both the hinge itself and the cabinet structure.

- Convenience: Users need not worry about slamming doors, as these hinges allow for a gentle and automatic closure.

Top Manufacturers in the Industry

Overview of Leading Cabinet Hinge Manufacturers

Several manufacturers have established themselves as leaders in the cabinet hinge market, offering a diverse range of products designed to cater to various needs. Some notable brands include:

- Blum: Renowned for their innovative hinge systems and soft-close technology, Blum offers high-quality options for both residential and commercial cabinetry.

- Amerock: This manufacturer is known for its extensive range of decorative and functional cabinet hardware, including a variety of hinges.

- Grass: Offering advanced hinge technology, Grass focuses on quality and state-of-the-art manufacturing processes.

- Tallsen: A significant player in the hinge manufacturing space, Tallsen provides high-quality solutions alongside cost-effective pricing, catering to global markets.

Comparative Analysis of Popular Brands

When selecting hinges, comparing popular brands can be beneficial. Here are some key aspects to analyze:

- Durability: Review customer feedback and durability testing results.

- Range of Options: Brands that offer a variety of styles and functionalities cater to a wider audience.

- Customer Service: Evaluate the support offered, including installation guidance and warranty policies.

Proper due diligence allows consumers to make informed decisions and choose the best product for their specific needs.

Case Studies: Successful Installations and Applications

Real-world applications of cabinet hinge solutions can illustrate their effectiveness and performance. For example, a luxury kitchen renovation that utilized Blum’s soft-close hinge systems not only improved functionality but also elevated the kitchen’s aesthetic appeal, winning design awards. In another case, a commercial furniture manufacturer adopted Tallsen’s heavy-duty hinges for their office furniture line, concluding that they improved product longevity, resulting in less hassle with returns and replacements.

Trends in Cabinet Hinge Design and Functionality

Innovation in Hinge Design: What’s New?

Innovation in hinge design continues to evolve, with trends reflecting the growing demand for both functionality and aesthetics. Key innovations include:

- Integrated Technology: Some modern hinges now feature integrated closing mechanisms that maximize ease of use and safety.

- Smart Hinges: With advancements in smart home technology, hinges are being designed to work with automated systems for opening and closing doors.

- Eco-Friendly Materials: Sustainable manufacturing practices and materials are becoming mainstream, appealing to environmentally-conscious consumers.

Sustainability Practices Among Cabinet Hinge Manufacturers

Sustainability has become a priority for many cabinet hinge manufacturers. Companies like Blum are pioneers in developing environmentally friendly products and operations. This includes using recycled materials in production and implementing processes that minimize waste. Consumers increasingly prefer brands that demonstrate a commitment to sustainability, which positively impacts brand loyalty and market growth.

Future of Cabinet Hinges: Predictions and Insights

Looking ahead, the future of cabinet hinge design is expected to focus on continued technological advancements, user-centric designs, and sustainability. As the demand for multifunctional spaces grows, hinge systems will likely adapt to support diverse functionalities, including electronic locking mechanisms and automated opening and closing features. Furthermore, the integration of voice technology in cabinetry could soon become a reality, shaping the kitchen and furniture design landscape for years to come.