Understanding the Needle Gun

What is a Needle Gun?

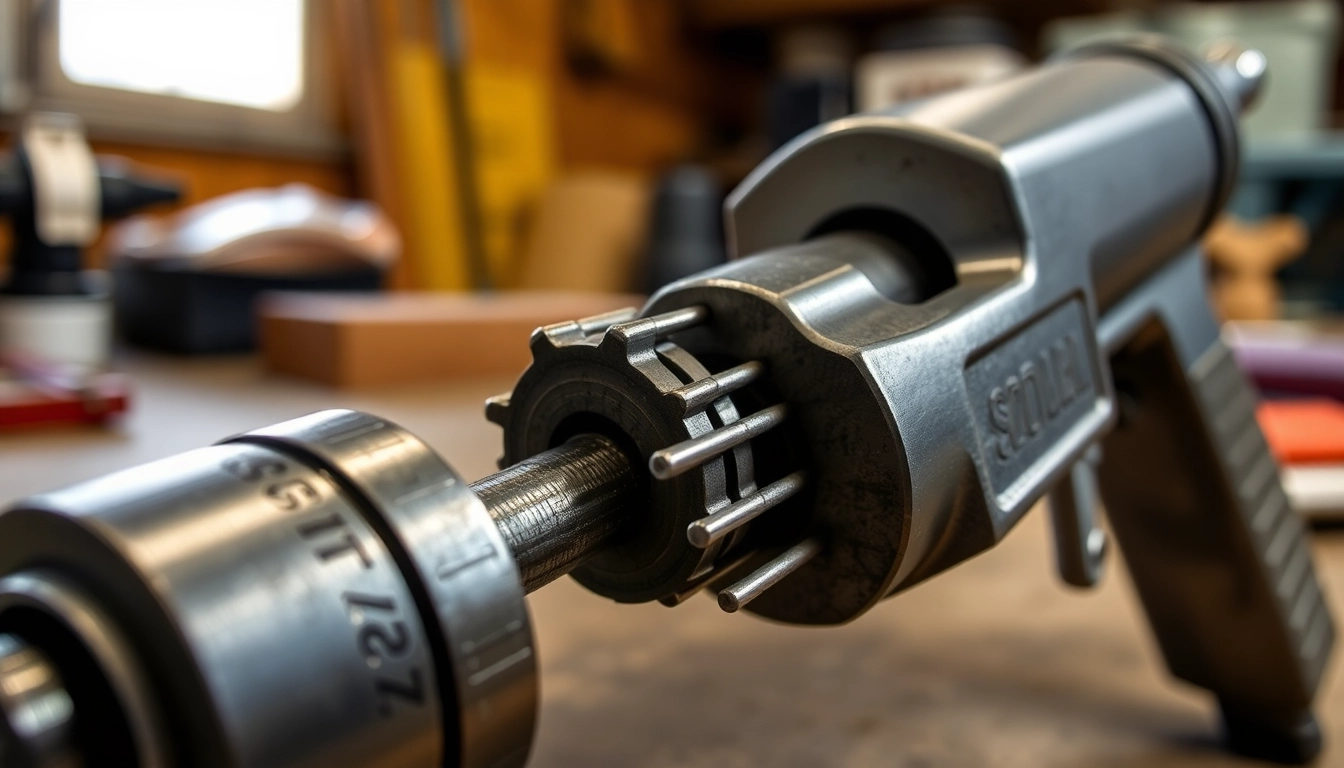

A needle gun, also known as a needle scaler, is a powerful pneumatic tool designed primarily for surface preparation. It utilizes an array of rapidly vibrating needles to remove rust, old paint, mill scale, and other contaminants from metal surfaces. The needles achieve this by delivering a hammering action that is effective in accessing difficult areas and contours, making it an invaluable tool in various applications, from automotive repair to ship maintenance. Its operation is based on compressed air, which drives the needles at high speeds, often up to 5,000 blows per minute. For those interested in acquiring a needle gun, understanding its functionality and capabilities is essential for optimal usage.

Common Uses of Needle Guns

Needle guns have a wide range of applications across different industries:

- Automotive Repair: Used for stripping paint and rust from body panels and restoring surfaces before repainting.

- Shipbuilding and Marine Maintenance: Essential for removing layers of salt, rust, and old paint from boat hulls.

- Manufacturing and Fabrication: Ideal for preparing metal components for welding or coating processes.

- Construction: Employed in the restoration and cleaning of metal structures and surfaces.

Types of Needle Guns Available

There are various types of needle guns, primarily classified based on their power source:

- Pneumatic Needle Guns: The most common type, these tools use compressed air to operate, providing high power and efficiency.

- Electric Needle Guns: Powered by electricity, these tools are quieter and require less maintenance but may not deliver the same power as pneumatic versions.

- Battery-Powered Needle Guns: A more portable option, suitable for remote locations where power supply is an issue.

Benefits of Using a Needle Gun

Improved Surface Preparation

One of the primary advantages of a needle gun is its effectiveness in surface preparation. The high-frequency vibrations of the needles allow for thorough cleaning, even in hard-to-reach areas, ensuring that the surface is well-prepared for coatings or further treatment.

Efficiency in Rust Removal

Rust and paint removal can be time-consuming when using traditional methods. However, a needle gun accelerates this process significantly. Its hammering action effectively dislodges rust and debris quickly, making it a time-efficient tool for professionals and DIY enthusiasts alike.

Cost-Effectiveness for Projects

Investing in a needle gun can be cost-effective in the long run. By reducing labor time and increasing surface preparation quality, users can complete projects faster and with less risk of surface damage, leading to better final results and reduced material costs.

How to Use a Needle Gun Safely

Essential Safety Gear

Safety should always be a priority when using a needle gun. Here are some essential safety gears to consider:

- Safety Glasses: Protect your eyes from flying debris.

- Hearing Protection: Wear ear protection to protect against noise.

- Respirator Mask: Prevent inhalation of dust and chemicals.

- Gloves: Ensure a firm grip and protect your hands.

Operating Instructions

To operate a needle gun effectively and safely, follow these steps:

- Connect the needle gun to a compressed air source and adjust the pressure according to the manufacturer’s guidelines.

- Wear all necessary safety gear.

- Hold the tool securely and position the needles at a slight angle to the surface.

- Apply consistent pressure and move the tool over the surface smoothly.

- Monitor the needles frequently for wear and replace them as necessary to ensure effective performance.

Common Mistakes to Avoid

In order to maximize the effectiveness of a needle gun while ensuring safety, it’s crucial to avoid common mistakes:

- Not wearing appropriate safety gear.

- Using the gun at incorrect air pressure, which can lead to ineffective cleaning or damage to the substrate.

- Failing to maintain the tool, resulting in reduced performance and increased wear on components.

Comparing Needle Guns with Other Tools

Needle Gun vs. Angle Grinder

While both tools are effective for surface preparation, the needle gun excels in delicate applications where precision is required. Angle grinders tend to generate heat and can warp surfaces if not used carefully. Needle guns, on the other hand, provide a gentler method for removing rust without altering the surface structure.

Needle Gun vs. Sandblaster

Sandblasting is a more aggressive method of surface preparation that uses abrasive particles to clean surfaces. Although it is highly effective for large areas, it can create a mess and might not be feasible for smaller or detailed tasks. Needle guns offer a cleaner and more controlled alternative for specific projects that require precision.

Choosing the Right Tool for Your Needs

When deciding which tool to use, consider factors such as the material you are working with, the size of the area to be cleaned, and the nature of the contaminants. For spots that require detailed work or delicate surfaces, a needle gun would likely be the superior choice, while larger projects may benefit from a sandblaster.

Maintenance and Care for Your Needle Gun

Regular Maintenance Tips

To ensure that your needle gun performs optimally over its lifespan, regular maintenance is crucial:

- Clean the tool after each use to prevent blockage of the needle holes.

- Lubricate moving parts according to manufacturer recommendations.

- Inspect needles regularly for signs of wear, replacing them as needed.

Signs of Wear and Tear

Being able to recognize when your needle gun needs servicing can save you from costly repairs down the line. Signs include:

- Decreased impact force or slowing of the needle movements.

- Increased air leakage or noise during operation.

- Visible damage to needles or the housing of the tool.

When to Replace Your Needle Gun

While with proper care a needle gun can last a long time, there are instances when replacement is necessary. If repairs exceed 50% of the cost of a new tool, or if performance is significantly compromised, it may be time to invest in a new unit. Always evaluate the tool’s effectiveness regarding your current and future projects.