Introduction to Electromagnetic Shielding Materials

What is Electromagnetic Shielding?

Electromagnetic shielding refers to the practice of blocking electromagnetic fields, which can be found in numerous applications across various industries. By using specific materials, electromagnetic interference (EMI) can be reduced or eliminated entirely, protecting sensitive electronic equipment from unwanted noise and ensuring reliable operation. Shielding is crucial in maintaining the integrity of signals in wireless communications, electronic devices, and even medical equipment.

Importance of Shielding in Modern Technology

In an age where electronic devices dominate our daily lives, the importance of electromagnetic shielding materials has never been more pronounced. These materials are key to the functionality and efficiency of numerous technologies, from smartphones to advanced healthcare instruments. With the proliferation of wireless technologies and the miniaturization of electronic components, the risk of EMI disrupting operations has escalated. For this reason, selecting effective electromagnetic shielding materials is essential to achieving reliability in design and performance across different fields such as telecommunications, computing, automotive, and healthcare.

How Electromagnetic Shielding Works

Electromagnetic shielding works through two mechanisms: absorption and reflection. High-conductivity materials, such as metals, reflect electromagnetic waves away from the sensitive components, greatly reducing interference. Simultaneously, specific materials can absorb EMI, dissipating its harmful effects instead of allowing it to reach critical parts of electronic systems. The choice of shielding material, its thickness, and configuration plays a vital role in the overall shielding effectiveness. Thus, understanding the fundamentals of how electromagnetic fields work and the materials used for shielding is indispensable for engineers and designers.

Types of Electromagnetic Shielding Materials

Common Metals Used for Shielding

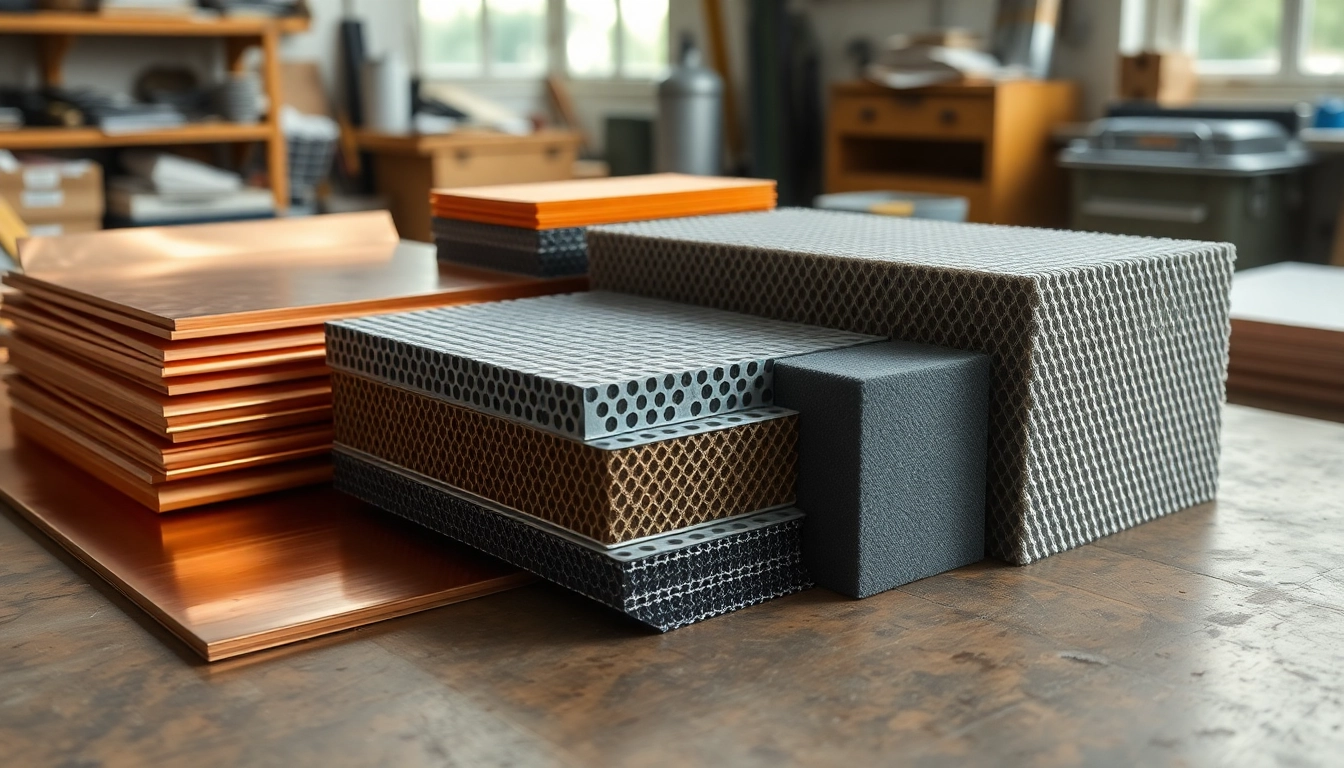

Metals are the most widespread materials used for electromagnetic shielding due to their excellent conductivity and ability to reflect electromagnetic waves. The most common metals employed include:

- Copper: Regarded as the best option for shielding, copper excels in both magnetic and electric wave attenuation. Its use ranges from simple applications in electronics to complex aerospace systems.

- Aluminum: Noted for its lightweight properties and lower cost compared to copper, aluminum serves well in applications requiring significant weight reduction without compromising effectiveness.

- Steel: Particularly stainless steel, provides robust shielding in demanding environments, often in the automotive and industrial sectors.

- Nickel: Frequently used in combination with other metals, nickel enhances corrosion resistance while providing effective shielding capabilities.

Polymer and Composite Shielding Solutions

Advancements in materials science have led to the development of polymer and composite shielding solutions. These are particularly appealing for applications demanding lightweight, flexible materials without sacrificing shielding performance.

Composite materials, often made up of woven fabrics mixed with conductive metals or conductive polymers, offer versatility in design. They can be tailored to specific shielding requirements and environments, making them suitable for applications in wearable electronics and telecommunications.

Natural and Organic Shielding Materials

In the quest for sustainability, researchers have begun to explore organic materials for electromagnetic shielding. While still in the early stages of development, these materials often harness the conductive properties of natural substances. For instance, certain biopolymers and carbon-based composites derived from hemp or bamboo are being investigated for their potential in creating eco-friendly shielding solutions.

The ongoing research indicates promising applications in fields seeking minimized environmental impact while ensuring device safety against EMI. Though traditional materials remain dominant, organic options may become viable mainstream solutions over time.

Applications of Electromagnetic Shielding

Use in the Electronics Industry

In the electronics industry, EMI shielding is critical for protecting sensitive electronic components from interference, which can result in performance degradation. Applications include:

- Consumer Electronics: Products like smartphones, laptops, and gaming consoles incorporate shielding techniques to ensure complete functionality in the presence of other electronic devices.

- Telecommunications: Antennas and communication devices heavily rely on effective shielding to manage signals properly and prevent crosstalk.

- Data Centers: As environments filled with complex electronic systems, data centers employ various shielding materials to maintain optimal performance and minimize interference between multiple servers.

Healthcare and MRI Facilities

Healthcare applications require strict adherence to safety standards, particularly when deploying sensitive devices such as MRI machines. Shielding in medical equipment mitigates the risk of noise from external electromagnetic fields, allowing for precise imaging and diagnosis. The use of specialized shielding materials, often combined with the architectural design of healthcare facilities, ensures a controlled environment that promotes patient safety and accurate test results.

Automotive Applications

The automotive industry has increasingly adopted electromagnetic shielding due to the rise of electric vehicles and advanced driver-assistance systems (ADAS). Shielding is imperative to protect the vehicle’s electronic control units (ECUs) from EMI generated by motors, batteries, and other electronic systems. Efficient shielding solutions contribute to the vehicle’s reliability and safety by preventing potential malfunctions or interferences from damaging sensitive electronics.

Best Practices for Selecting Shielding Materials

Evaluating Performance and Cost

When selecting electromagnetic shielding materials, evaluating both performance metrics and cost is crucial. Performance generally includes shielding effectiveness (SE), which indicates how well a material can reduce EMI. It is critical to conduct tests, such as those guided by the IEEE or MIL-STD standards, to ensure that the chosen material meets the application’s requirements.

Furthermore, the cost of these materials can significantly affect the project’s budget. Manufacturers should balance cost with performance, often by looking for materials that provide the best value without compromising on shielding effectiveness.

Considerations for Material Thickness

Material thickness plays a pivotal role in shielding effectiveness. As a general rule, thicker materials typically offer more protection; however, the weight and cost implications must be studied. The ideal thickness often depends on the frequency range and nature of the electromagnetic interference. For instance, higher frequencies require thinner shields for effective attenuation, while low frequencies benefit from thicker materials.

Balancing Flexibility and Strength

Selecting shielding materials that balance flexibility and strength is paramount, particularly in applications where materials must conform to specific shapes or withstand mechanical stress. Customizable laminations or flexible composites can provide optimal solutions to meet both structural and shielding performance requirements while accommodating design constraints.

Future Trends in Electromagnetic Shielding

Innovative Materials on the Horizon

The future of electromagnetic shielding lies in innovative materials designed to enhance efficiency while adapting to the ever-changing technological landscape. Research is underway into nanocomposites that leverage the properties of materials at the microscopic level, potentially revolutionizing shielding effectiveness while maintaining lightweight characteristics.

Emerging research in metamaterials, which exhibit unique properties not found in nature, also promises new solutions, providing previously inaccessible levels of EMI attenuation.

Regulatory Changes and Their Impact

As the reliance on electronic devices continues to grow, regulatory agencies are implementing stricter EMI regulations to protect consumers and businesses. These regulations may encompass testing methods, material certifications, and product safety standards, impacting how manufacturers choose and implement shielding solutions.

Keeping abreast of these changes is essential for manufacturers striving to maintain compliance while ensuring their products remain competitive in the marketplace.

Research and Development Focus Areas

Ongoing research in electromagnetic shielding materials focuses on enhancing performance characteristics, developing environmentally friendly alternatives, and creating multifunctional materials capable of offering both shielding and other benefits such as heat resistance or structural support. These avenues promise exciting future developments that may change the way electromagnetic shielding is approached in various industries.